Nestled in the heart of the Daniel Boone National Forest is the Fitchburg Furnace – once the largest iron furnace in the world. Also known as the Red River Furnace, its twin stacks operated only from 1869 to 1873.

The Furnace and Fitchburg

In 1791, the first ironworks began operated in Kentucky. By the 1830s, Kentucky was the third-leading producer of iron in the United States. Throughout the commonwealth remnants of these furnaces dot the rural landscape. But the Fitchburg Furnace was significant if for no other reason than its scale.

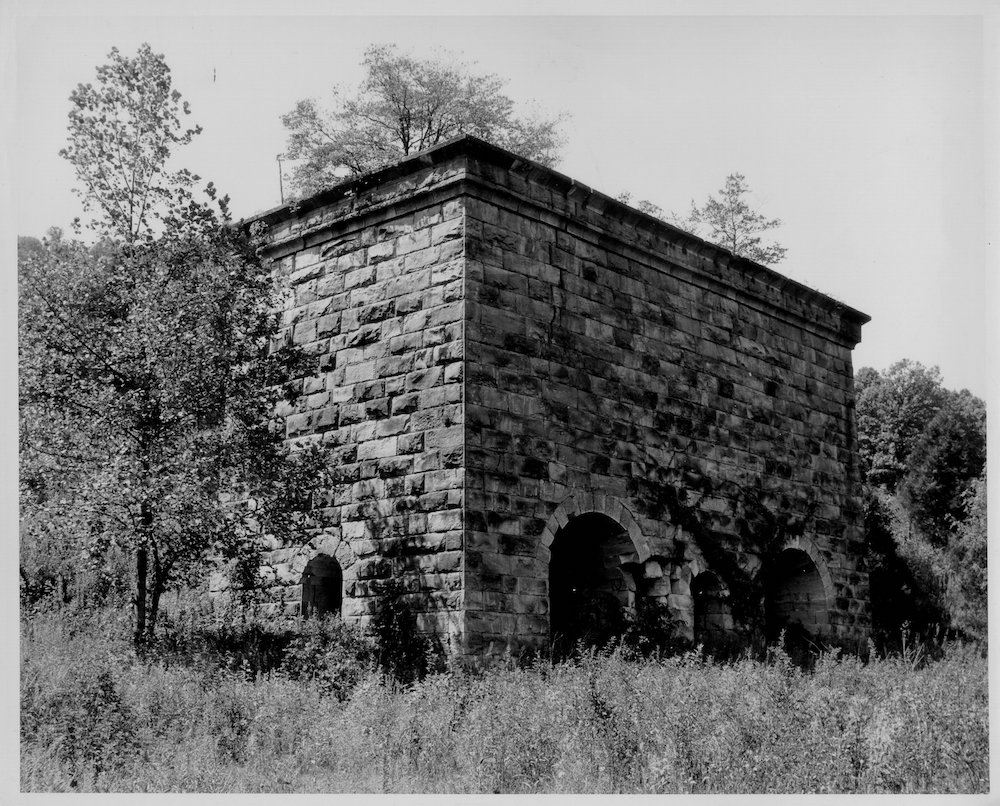

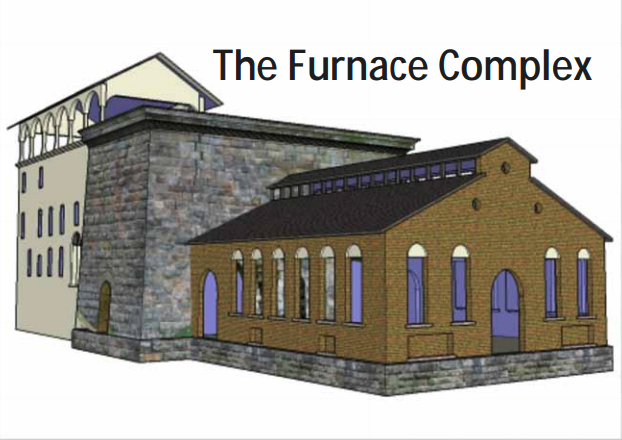

The furnace at Fitchburg is constructed of sandstone – its base forty by eighty feet. The structure stretches sixty feet into the heavens. Sixty feet may not seem like much, but the scale of this structure (150+ years old) in a rural part of Estill County is stunning. Although the furnace is all that remains of the iron-production operation, a powerhouse once flanked its rear while a casting shed stood in front.

The Furnace consisted of two twin stacks, while most Kentucky furnaces had only one. The stacks were named Blackstone and Chandler: each was fifty feet tall and 12.5 feet across on the inside. Together, the furnace could produce 25 tons of pig iron each day. Pig iron is an unfinished iron that requires further time in another furnace before becoming a usable product like wrought iron, cast iron, or steel. The pig iron forged at Fitchburg was shipped via flatboats to iron manufacturers in Cincinnati and beyond.

Brothers Frank Fitch and Fred Fitch developed the furnace when, in 1866, they established the Red River Iron Manufacturing Company. In 1867, Frank Fitch was quoted as saying that “I will design a furnace such as has never been seen before in these parts.” To accomplish this aim,

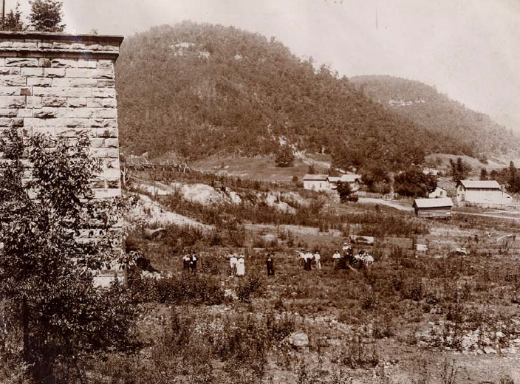

A furnace, however, does not stand alone. The power house and casting shed, too, are only a small part of the operation. At its height, over 1,000 people made up the community of Fitchburg to work at the furnace and to work in industries supporting, feeding, and taking care of those workers and their families. The community, of which today there is no physical evidence, once included stores and churches. It had a jail, a doctor’s office, and a hotel. In 1870, Fitchburg, Kentucky had approximately the same population as Nicholasville, Kentucky.

Panic and Ore

At this time in American history, railroads would begin to cross the nation. The first transcontinental railroad was finished by the driving of the golden spike at Promontory Point, Utah, around the same time as Fitchburg opened. Railroad companies and others invested in furnaces like Fitchburg and most of the iron from the furnace would have been utilized to produce rail and wheels for this industry.

Only a few years after the Fitch brothers opened their furnace, the bubble burst for railroad speculation. With that, the price of iron dramatically fell.

And if you’ve ever been to Birmingham, Alabama – the Pittsburgh of the South – you’ve undoubtedly see the statue atop a mountain to the Roman god of the forge, Vulcan. In the early 1870s, quality ore deposits were discovered in Alabama. It became far more efficient, and less expensive, to extract and forge iron in Alabama than from the hills of eastern Kentucky.

The Site Today

Even faster than it appeared, Fitchburg disappeared. The formidable stone furnace remained. By 1895, only the furnace and power house seemed to remain. In 1968, a US Forest Service employee began researching the site. Five years later, descendants of Frank Fitch donated the site – consisting now of only about two acres – to the United States Forest Service. It was added to the National Register of Historic Places the following year, 1974.

It was not until 2001 when there became a focused effort to restore the deteriorating structure. Reports indicated that the furnace itself (the only remaining structure) was within five years of a total collapse. Over the next decade, significant work was done to preserve this important piece of Kentucky’s industrial past.